|

1

ONWARD TO THE PAST

As theу soften the stone. As theу soften the stone.

Sigiriya. Part 4. "Throne Room".

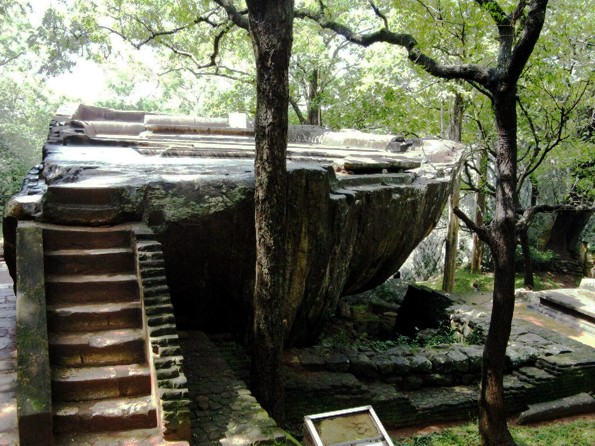

Every tourist who mastered climbing on Sigiriya seeks to visit surely the main attraction of Lion rock - the so-called "Throne Room" or "Reception hall". The main because it is the only place in the entire complex, which can be associated with something living and well equipped.

The object is a flat area with the size of 8x10 meters, in depth of which is "the throne" - a stone bench. Platform is surrounded from three sides with a semi-circular board, which on the left side has a flat rectangular recess, apparently a place for the clerk. All this is made from the mother monolith and is an integral whole with the rock. However, there is one component element on the right board, it differs in color, but we'll talk about it later.

|  The whole composition is processed top of huge boulder, the upper part of which was cut approximately up to half. For the lifting to the "Throne Room" the ladder has been put to the boulder which also itself is a very interesting object, because consists partly of monolith partially of blocks, partially of brick. The whole composition is processed top of huge boulder, the upper part of which was cut approximately up to half. For the lifting to the "Throne Room" the ladder has been put to the boulder which also itself is a very interesting object, because consists partly of monolith partially of blocks, partially of brick.

Ladder speaks eloquently about working methods of builders. In given case suitable lump by volume they melted and formed the main part, then, where the solid rock was not enough, added blocks and board laid with bricks. No unnecessary movements.

Still, the "Throne Room" looks unfinished, a little unfinished, such impression that the builders just left for lunch.

The whole plane of "Throne Hall" is quite strong tilted to the left, or rather, to the far left corner what says, judging by the rest products, about the probable inability to change this situation.

It would be assume that the boulder sank with time, but judging by the seam between the monolith and the ladder, it did not move for inch. |  Let us look at the "Throne Room" closer. We see again the same figured dumps with semicircular shape, which we saw before, and exactly the same "sofa" as standing in a deep recess, only the local is longer. Let us look at the "Throne Room" closer. We see again the same figured dumps with semicircular shape, which we saw before, and exactly the same "sofa" as standing in a deep recess, only the local is longer.

It can be explained with overall style, but it can be explained with limited set of figured profiles.

Looking at this picture, it is hard to escape from feeling that in viscous mass they pressed in figured form, which then pulled out. Excess rock was squeezed in all sides and the print remained on the surface.

|  If you look at the picture, then on the left side of the monolith you can see typical dents, similar to the ones, which we saw on the big boulders. Where melted the rock, it cannot do without them. If you look at the picture, then on the left side of the monolith you can see typical dents, similar to the ones, which we saw on the big boulders. Where melted the rock, it cannot do without them.

From right and in front rectangular grooves are visible, which run along the edge of the cliff.

Now, we have come close to that in order to understand, at least, approximately, as the product was created. Let us try to restore the whole process in order.

The first thing that has been done. With a big car they removed (leveled) the upper part of the boulder, leaving, where it is necessary required amounts. On this the mission of "rough" machine was finished.

Then it was time of another machine - walking 3D sculptor, which was set above the surface of the stone. Most likely, the rectangular slots on the right side, served for rigid attachment, and the left side was mobile.

|  Small flat rectangular area, which is also on the left, with a high probability is also relevant to 3D sculptor, because it has flatter horizon, and it has a pair of holes that go with a certain step. Small flat rectangular area, which is also on the left, with a high probability is also relevant to 3D sculptor, because it has flatter horizon, and it has a pair of holes that go with a certain step.

Most likely, it was stationary vibrator, such as those, which ram asphalt or gravel. Only here it was attached to the stone through the holes and may be provided flexibility while was working "sculptor". Therefore, the area has a smooth horizon. It leveled off under the weight of the vibrator. But this is only speculation.

|  Starting from the far side, 3D sculptor start to work. Having made a "throne" and the rear board, it moved back, making a lateral boards and a leveling off floor. Starting from the far side, 3D sculptor start to work. Having made a "throne" and the rear board, it moved back, making a lateral boards and a leveling off floor.

On the topper image to the left from the dog, we see how little material was not enough, and in the end was the influx. Exactly as happens when they level concrete screed with rail.

On the right side of the boulder we see two left border, which create a sense of recent works. How did they get here is unclear. Curbs are clearly from the pools. Perhaps there were extra ones there, but here they wanted to melt them and finish right ledge.

In general, all rejected product was due to the fact, that the "sculptor" simply had no enough material. Where material was he did there, and where it was not ... It is, therefore, more or less clear principle of the unit operation - it optimizes and distributes the available volumes of material in a desired 3D model.

|  Having finished with the main platform "sculptor" stepped vibrator, and for the first time put his support on the left side of the boulder. Then anyone can count how many steps yet made 3D sculptor. He made five steps more and with the last step stamped his footing completely. So, we have a genuine full print of alien mechanism support. Having finished with the main platform "sculptor" stepped vibrator, and for the first time put his support on the left side of the boulder. Then anyone can count how many steps yet made 3D sculptor. He made five steps more and with the last step stamped his footing completely. So, we have a genuine full print of alien mechanism support.The support was complex and consisted of a multi-level individual paws. A hole is a rod, which does allow to slip the unit. Rather it does not slip, but it feels on the rod more confidently. Therefore, having made another step on the third, it saw that there is enough space, and the edge will not break off, and it immediately tried to put the rod.

Also, "sculptor" must take into account the size of 3D model in space of which it can not intrude. Therefore, having found itself in a permissible zone "sculptor" confidently stood up on two legs and apparently having finished the work it stood up on all support completely.

It is interesting, that two steps on a boulder for future ladder they probably made simply "manually", literally with a shovel until the "solution" did not solidify. But, the main thing they did not forget.

|  Summing up a short result to all foregoing we can say that these technologies of work with stone, remove many questions, which puzzled of thinking people who do not believe, that Egyptians could build the Great Pyramid. Summing up a short result to all foregoing we can say that these technologies of work with stone, remove many questions, which puzzled of thinking people who do not believe, that Egyptians could build the Great Pyramid.

Trilithons of Baalbek nobody moved, they were cast on the spot. Therefore, you can not stick anything between them. It is clear more or less with polygonal laying 3D sculptor worked. "Buttons", "nipples" and other holes all these are technological marks of the machine.

Therefore, Egyptian obelisks have such quality, and therefore split off a thin layer (casting plus hardening) on them. Any stone columns and sculptures can be replicated thousands. Therefore, they are so similar. There are no problems with casting of any blocks, colossal statues and other monuments.Old men in Axum, long ago talked – steles were cast by giants in the formwork and then placed.

Sarcophagus are such even and smooth because formwork was ideal. They entered through the narrow passages because at the time of penetration were plastic rock mass, and solidified already in place.

In one word, now thanks to fine Sigiriya, you can slightly imagine what are real machine technologies in construction and what is advanced civilization. But, where all this has disappeared ... Printer that prints with bricks! My head does not fit.

| | All photos used in this article are taken from the site of A.V. Koltypin dopotopa.com |

Author: © GeoLines.ru Copying prohibited

|